A Superior Product

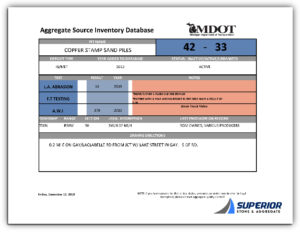

The state-owned stamp sand stockpiled at the Gay, Michigan site represents the largest mined, pre-crushed, ideally sized aggregate source in Michgian.

Technical Analysis

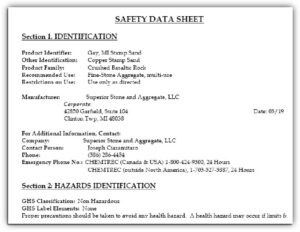

Stamp sand is a natural basalt rock which was mined for its copper content. During the mining process, the basalt rock was crushed into a rock sand material called stamp sand. Stamp sand portions high in copper concentration were sent to the smelter for metal production, low concentration sand was not further processed and stockpiled on local beachfronts or other locals.

Quantity Availability

The State of Michigan approximates 15 million tons of material available at the Gay, MI Buffalo Reef Site.

Rights to Material

The material at Gay, MI is owned by the State of Michigan. Regulatory agencies (MDEQ, Army Corp. of Eng., EPA) along with local municipalities have granted permits to allow private firms to potentially market and distribute stamp sand into various markets.

Market Analysis

Total road aggregate market for Southeastern MI is ~3.5 million tons annually varying with state funding designated for road improvement projects. Stamp sand can be marketed as road base, (MDOT Spec.) 2NS sand or “bridge aggregate” within asphalt mix designs. Projected annual sales volume is projected to reach +500,000 tons by year 3 of operation. Duration of bulk shipping vessel season (Rand Logistics estimate, 2019) and limitations of existing local infrastructure (deep water port capacity) dictates maximum yearly tonnage transported to market. Within our projected sales region (Southeastern, MI), road building aggregate market is tightening. Currently, limestone is being imported from Northern MI and other Great Lakes regions to augment its supply (per: Detroit Bulk Storage market data, 2019). Consequently, pricing of bulk limestone has increased: ~$10/ton (2018) to ~$12.25/ton (2019). This trend is projected to continue for the next 5 years or longer. Difficulty of obtaining new quarry/pit permits near developing neighborhoods, environmental concerns and scarcity of exploration sites are limiting new sources of aggregate supply. Superior can provide stamp sand to mitigate this shortfall for a decade or more by directly supplying this market. (see: Submittal Document II.B. Southeast Michigan Aggregate Market Study, prepared by Edw. C. Levy Co., Nov. 10, 2015)

COMPETITIVE ADVANTAGES

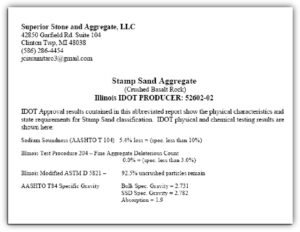

Relative to existing road aggregate material (limestone, crushed concrete, stone sands), basalt rock (stamp sand) possesses superior physical and chemical properties. State DOT standardized (ASTM) testing and proprietary mix design trial data shows stamp sand outperforming competing aggregates. The following are vital quantifiable qualities essential to each specific aggregate usage: (see Appendix B-E)

Road Base

- High compactability – produces more stable road base significantly improving asphalt and concrete roadway longevity.

- Reduced reactivity to salt(s) and de-icers – reduced chemical reaction/deterioration due road salt application.

- Increased Drainage – allows rainwater/meltwater drainage reducing freeze/heaving.

Asphalt and Concrete Products

- Abrasion Resistance – high strength rock aggregate resists particle deterioration as quantified by low Los Angeles Abrasion testing (14%). Competing aggregate deterioration rate much higher, ~20%-25%.

- High Angularity – increased angular particle shape produces denser, stronger asphalt at more competitive pricing. Eliminates need for costly aggregate mixing to achieve similar angularity values.

- Reduced Absorption- aggregate particles absorb less costly asphalt bituminous binder significantly reducing per ton production price. Absorption value = 1.7 -1.9

- Extremely Low Alkali/Silicon Reaction (ASR) Value – basalt rock is far more resistant to the concrete deterioration process known as alkali/silicon reaction. Basalt rock aggregate out performs all competing aggregates and registered as the lowest reactive aggregate tested. ASR avg. expansion = 0.014%

© 2023 Superior Stone & Aggregate LLC | Designed by Brandslam Promos